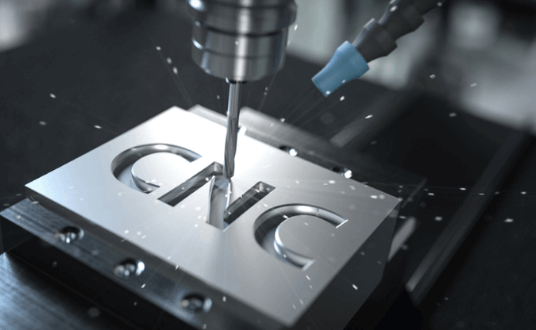

CNC Machining Methods of Aluminum

CNC (Computer Numerical Control) machining is a versatile and precise manufacturing method used to produce aluminum parts with various shapes and sizes. There are several CNC machining methods commonly employed for aluminum, each suited to specific applications. Here are some of the primary CNC machining aluminum methods:

Milling:

3-Axis Milling: This is the most common form of CNC milling, which involves the use of a cutting tool (end mill) mounted on a rotating spindle to remove material from the aluminum workpiece along three axes (X, Y, and Z).

4-Axis and 5-Axis Milling: These advanced milling techniques allow for more complex and contoured parts, as the cutting tool can move along additional axes. 4-axis milling includes rotational movement, while 5-axis milling adds tilt to the tool.

Turning:

CNC Lathe Turning: In this process, a single-point cutting tool removes material from a spinning aluminum workpiece to create cylindrical or conical shapes. CNC lathes are commonly used to produce aluminum shafts, pins, and other rotationally symmetric parts.

Drilling:

CNC Drilling: CNC machines can be used for precise hole drilling in aluminum parts. This is commonly used for creating holes for fasteners or to pass fluids and wires.

EDM (Electrical Discharge Machining):

Wire EDM: EDM uses electrical discharges to cut through the aluminum material, making it suitable for intricate and delicate parts. Wire EDM is often used for tool and die manufacturing and for producing small, precise components.

Grinding:

CNC Grinding: CNC grinding machines are used for precision surface finishing and shaping of aluminum parts, particularly in applications where tight tolerances and fine surface finishes are required.

Waterjet Cutting:

CNC Waterjet Cutting: High-pressure water mixed with abrasive particles is used to cut aluminum sheets into precise shapes. Waterjet cutting is a cold cutting process, making it suitable for materials that can’t withstand heat.

Plasma Cutting:

CNC Plasma Cutting: This method uses a high-velocity jet of ionized gas (plasma) to cut through aluminum sheets. It’s commonly used for thicker aluminum plates and structural components.

Routing:

CNC Routing: This method is similar to milling but is typically used for larger, flat aluminum sheets and plates. It is common in the production of signage, panels, and aerospace components.

Engraving and Marking:

CNC Engraving and Marking: This process uses CNC machines to engrave or mark text, symbols, or designs onto the surface of aluminum components. It’s often used for branding, part identification, or decorative purposes.

These CNC machining methods can be used individually or in combination to produce complex aluminum parts with high precision and accuracy. The choice of method depends on the specific requirements of the part, such as its geometry, tolerance, and surface finish, as well as the material properties of the aluminum being used.

Xielifeng Tech is a reliable CNC machining factory from China. With the help of advanced CNC machining technology, it can manufacture aluminum parts right according to your drawings with fine workmanship. Welcome to inquiry if you need to make some parts. Generally, you will get the quote within 24 hours.